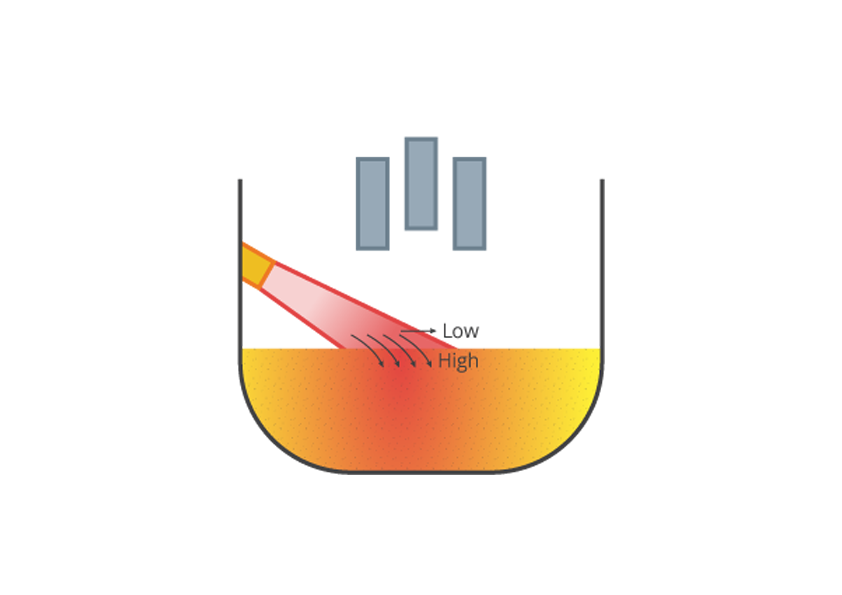

This burner developed by Soudobeam is the fruit of an innovative and flexible design thanks to which the flame configuration can be optimised for each steel plant. It can be water cooled or not in accordance with the inputs available on the electric arc furnace (EAF).

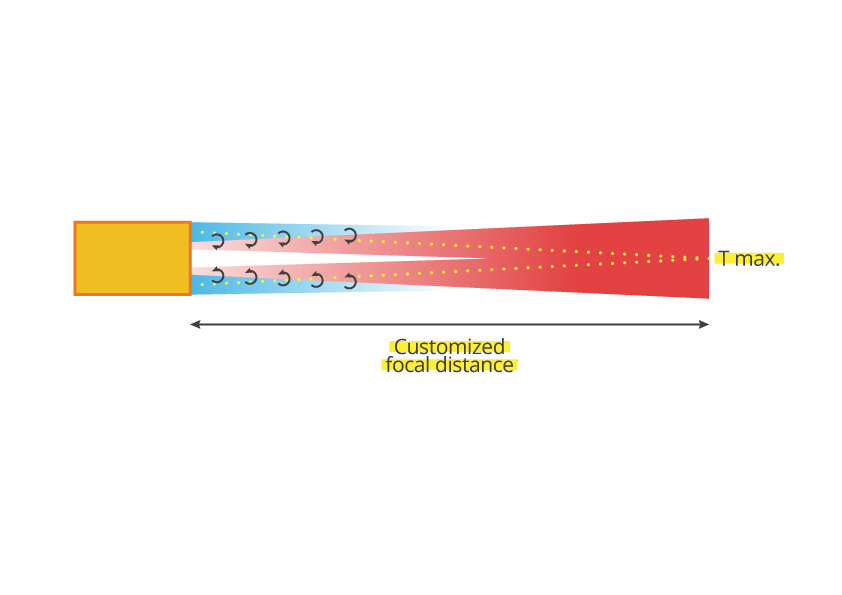

Thanks to injection technology that produces high combustion yield and gives optimum positioning to the hottest zones, the Soudobeam burner is the essential tool for productivity and savings in electric arc furnaces.

Energy gains

The optimised flame, with or without a mixing chamber, helps to bring combustion as close as possible to the surface in order to produce a significant and swift thermal transfer to the scrap metal.

- Removal of cold zones

- Decrease in electricity consumption

- Less heat loss in the lining and atmosphere

Productivity and safety

The combustion yield increased by whirling injection technology improves the efficiency and density of combustion to provide a greater input of heat.

- Acceleration of scrap metal fusion

- Reduction of emissions

- Decrease in the electric power required

Durability and robustness

It has been designed to resist the most severe stresses encountered in the methods and processes specific to each steel plant.

- Tolerates different locations in the furnace

- Robust against projections of slag

- Increased resistance to flame blow-back