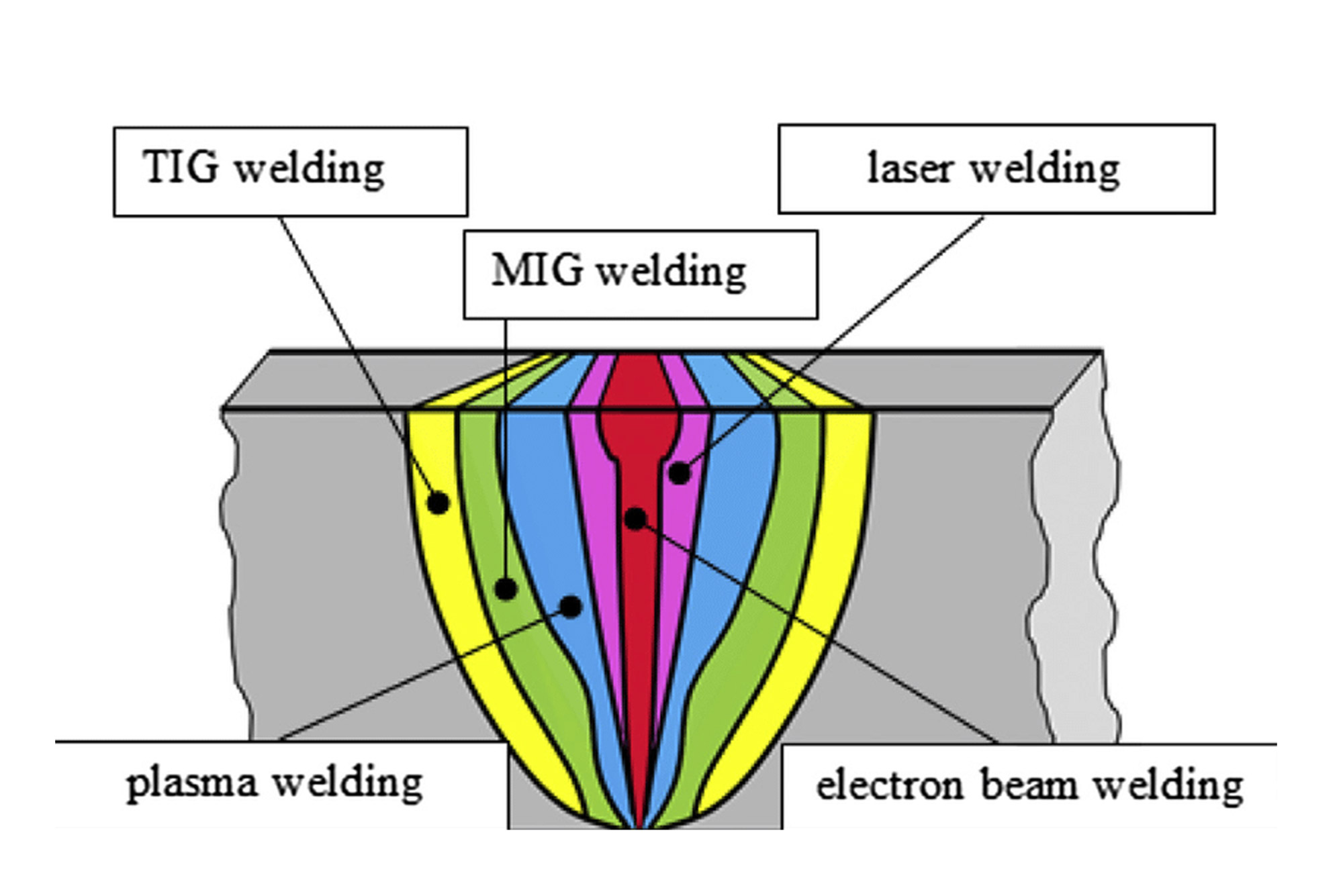

Soudobeam provides metal component assembly services using electron beam welding. This high energy density vacuum welding process provides metallurgical quality and mechanical resistance that are superior to conventional processes.

We are able to handle small to large series from development onwards. We also possess in-production control resources and machining capacities that enable us to take charge of preparing welded joints and the necessary tools.

Soudobeam’s products boast several hundred uses, in domains such as general engineering, aeronautics, electrical engineering, medical appliances and special applications in particular.

From thin to thick

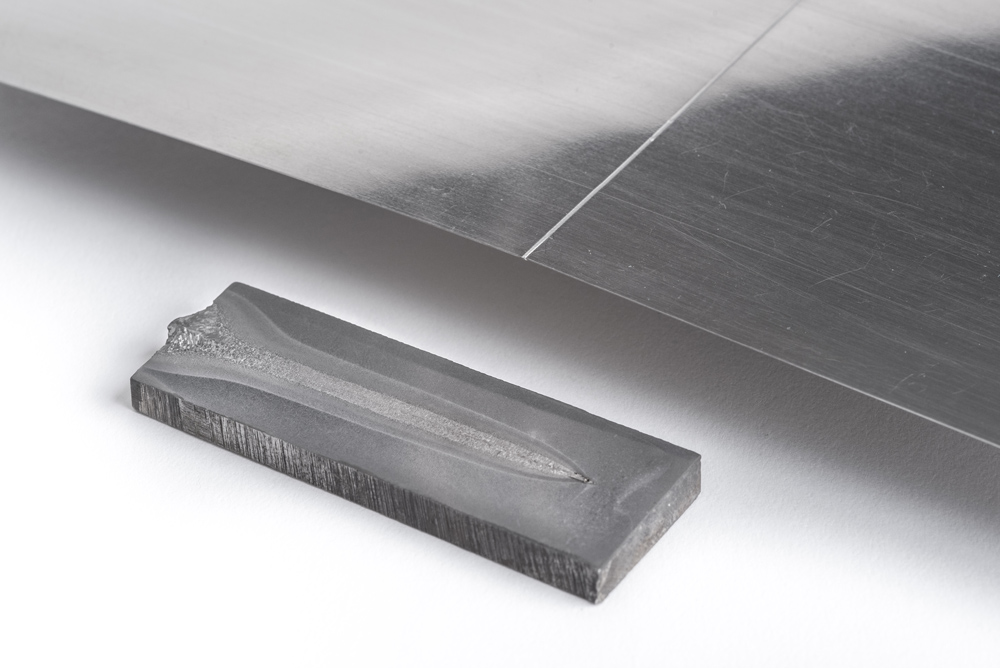

The electron beam possesses many adjustment parameters, making it possible to precisely adjust penetration over a very broad range.

- From 0.2 to 50 mm in one single pass

- A variety of different thicknesses is possible

- Small and large parts can be manufactured

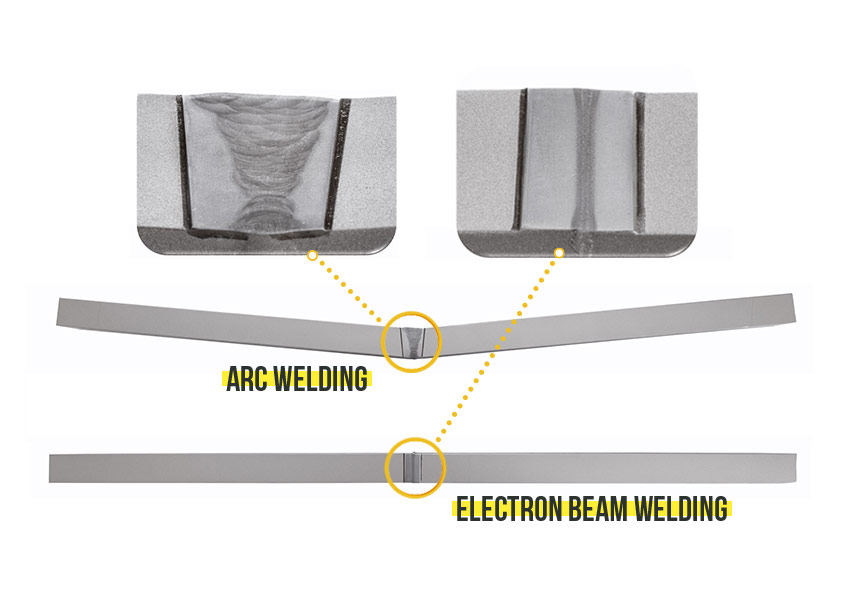

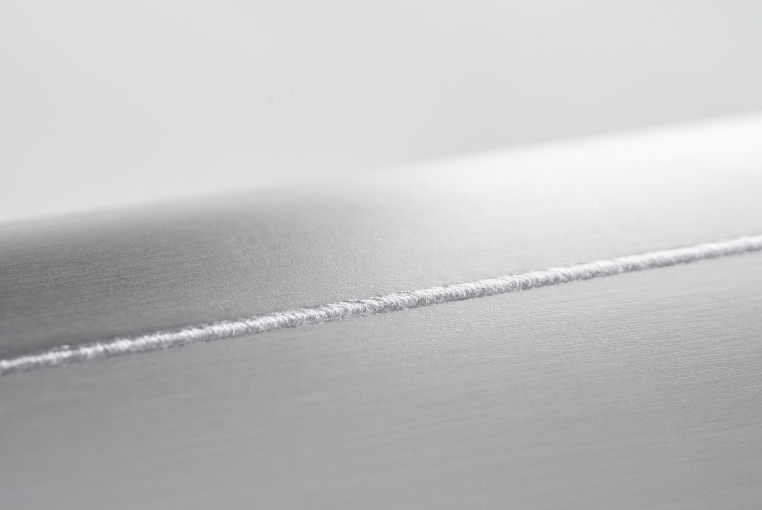

Very few constraints and deformations

Thanks to very localised fusion and a very narrow bead with parallel edges, welding shrinkage is very low and angular deformation is negligible.

- Ideal for precision mechanics

- Welding on finished components without later re-machining

- High mechanical resistance

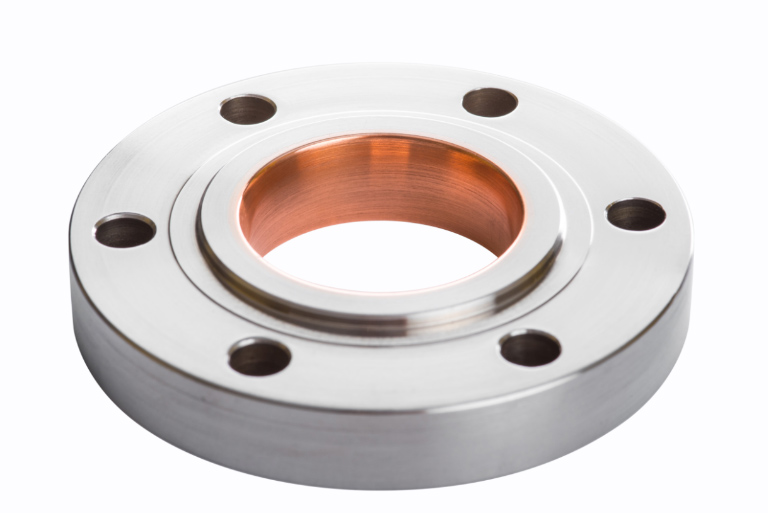

A wide variety of materials

Thanks to its high energy density, the process is especially well-suited to materials with high heat conductivity as well as heterogeneous bonds. The welding is conducted in a vacuum, making it possible to obtain excellent quality on very reactive materials.

- High heat conducting materials such as copper or aluminium

- Dissimilar, reputedly difficult bonds such as steel with copper

- Materials such as titanium, tantalum, nickel, Hastelloy or Inconel

Excellent metallurgical quality

The combination of a weld bead made without filling of metal, of a very narrow heat affected zone and a vacuum operation provides excellent metallurgical quality to the welded bond.

- Metallurgical homogeneity

- No cold cracking

- High resistance to mechanical, thermal and chemical stress

Accessibility in confined spaces

Due to its long reach and narrowness, the electron beam is capable of reaching very confined zones that cannot be accessed by any other process.

- Offers a wide range of component design freedom

- Enables transparent welding

- Simultaneous multiple bonds

A quick and reliable process

Electron bombardment welding is fully automated, making it possible to reach high welding speeds and a high level of replicability.

- High levels of productivity

- Constant quality from piece to piece

- Precision adjustment possible

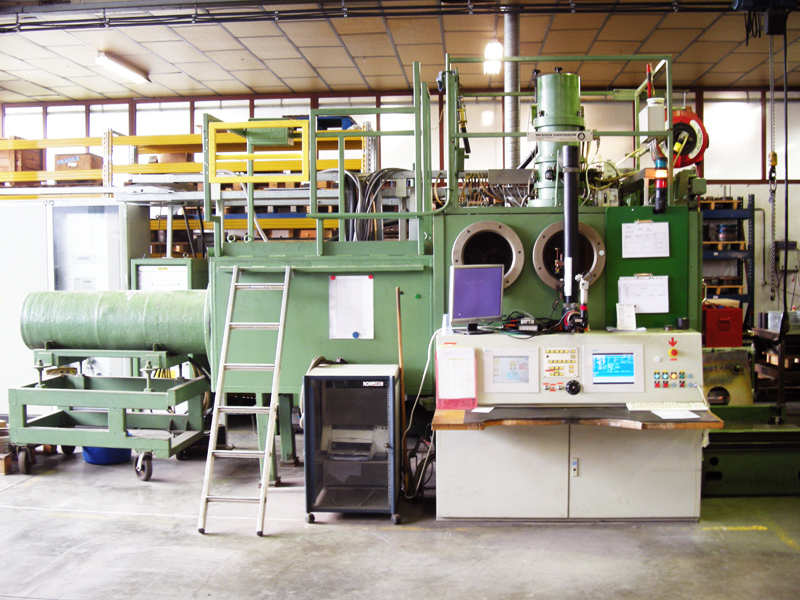

Our equipment

Our EBW welding machine is equipped with a 15-kW electron beam gun, with accelerating voltage of 150kV. It is equipped with an X-Y traversing unit and a numerically controlled rotating unit.

- Volume of the main work unit 1.200 x 1.200 x 1.600

- Volume can be extended

- Maximum weight of parts to be welded 1,200 kg