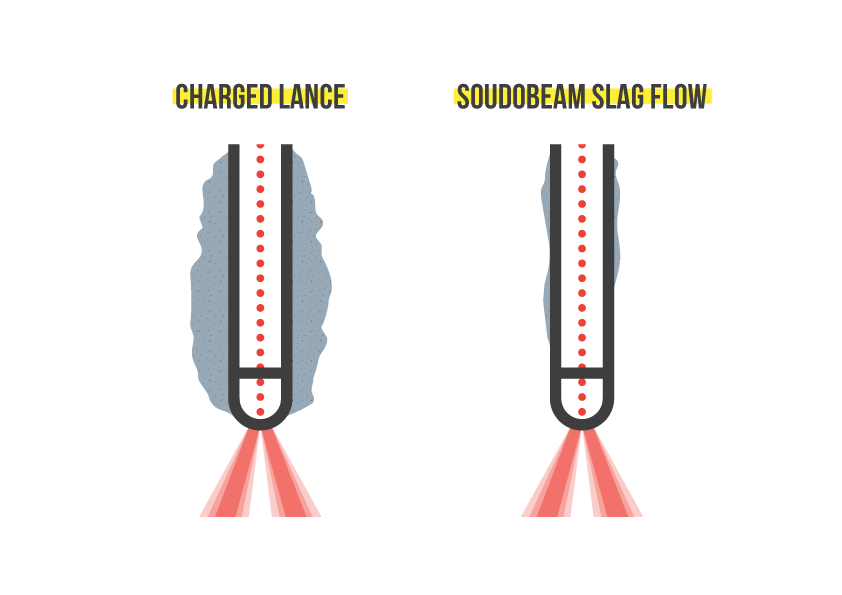

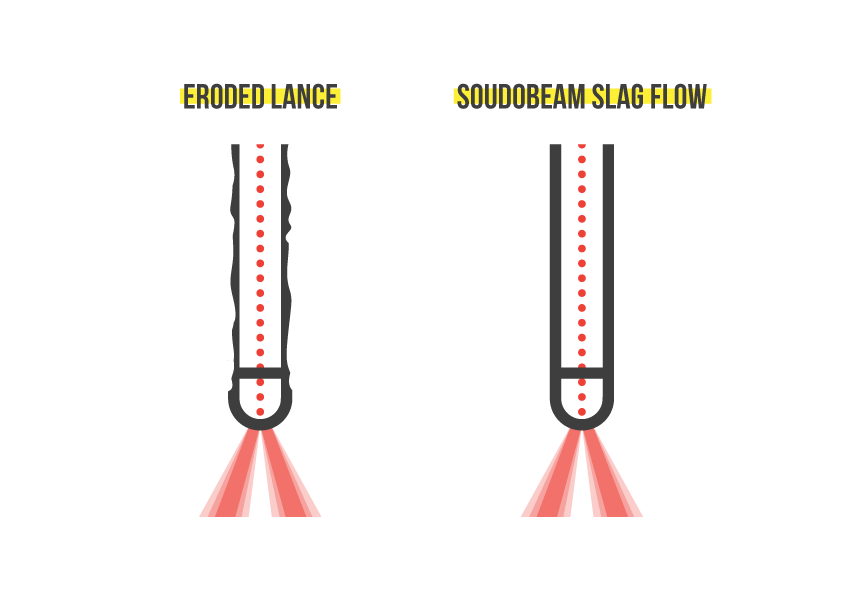

This oxygen lance barrel developed by Soudobeam uses slag flow technology to reduce the problems caused by appearance of skulls and wear of lances in LD (BOF) steel-making. It is mounted as a replacement for the end section of an existing lance.

Slag flow is a combination of advanced computer-assisted design and the use of a low-adhesion alloy. This technology is a tool for diminishing risky maintenance operations and production downtime for cleaning or replacement work.

Gains in productivity

The innovative design of this lance means it has reduced binding with the slag, helping to diminish clinging of skulls and to lower maintenance time.

- Less downtime for lance cleaning

- Easier lance cleaning

- Greater safety for maintenance operators

Reduced Maintenance

The lining of this lance displays low affinity with the slag and a vastly reduced erosion rate, meaning it can be used for longer before the barrel needs to be replaced.

- Longer lance service life

- Decrease in maintenance costs

- Better dimensional stability

Easy assembly

The leak-tight customised quick insertion and fast removal system for the lance barrel means it can be commissioned and replaced more quickly.

- Simple and quick assembly

- Lance-dedicated interfaces

- Adaptable to all lances