The SoudOxAr ® Mono supersonic axial injection lance tip has been developed to combine preservation of refractory lining with rapid and uniform decarburization, by the use of a single high density central tuyere in AOD conversion.

The single supersonic jet is custom-calculated to feed the gas into the heart of the bath providing a considerable transfer of energy. It is a tool for the stability of metallurgic results and durability of refractory lining.

Quicker decarburization

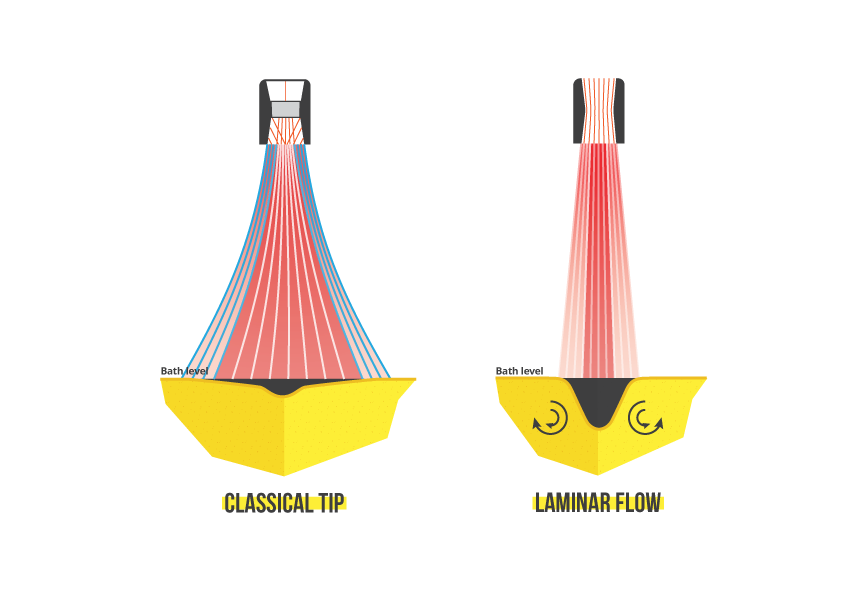

The injection tuyere specially designed to produce a jet with high density kinetic energy provides agitation and chemical reactivity in the bath.

- Greater kinetic and chemical agitation

- Uniformity of bath composition

- Extensive penetration and convection of gas

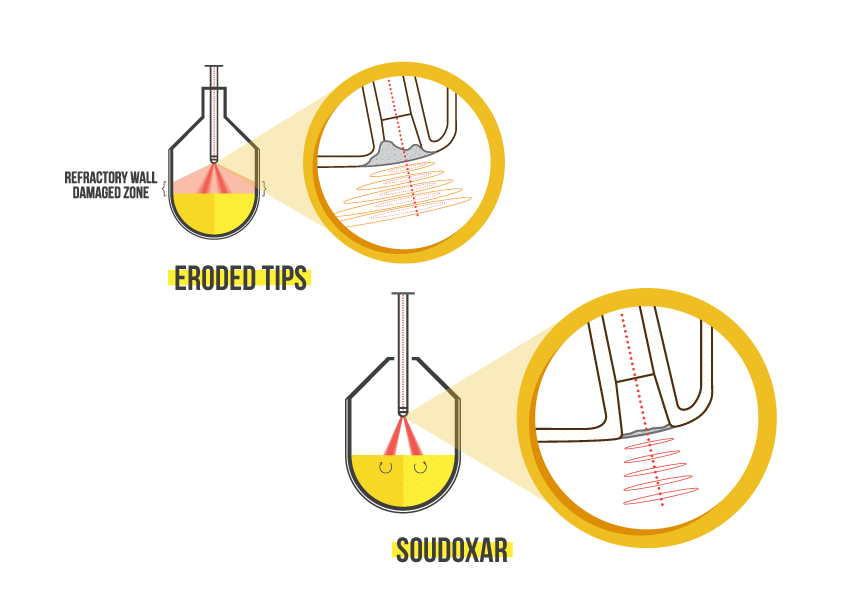

Reduced Maintenance

A lance head with low level degradation conserves concentrated blowing capacity that does not affect the refractory lining, providing distinct penetration and few projections.

- Increased service life

- Few projections

- Insignificant effect on refractory lining wear

Flexibility

It is a tool designed to be adapted to operating conditions in each steel plant, whilst tolerating the usual variations in the blowing pattern.

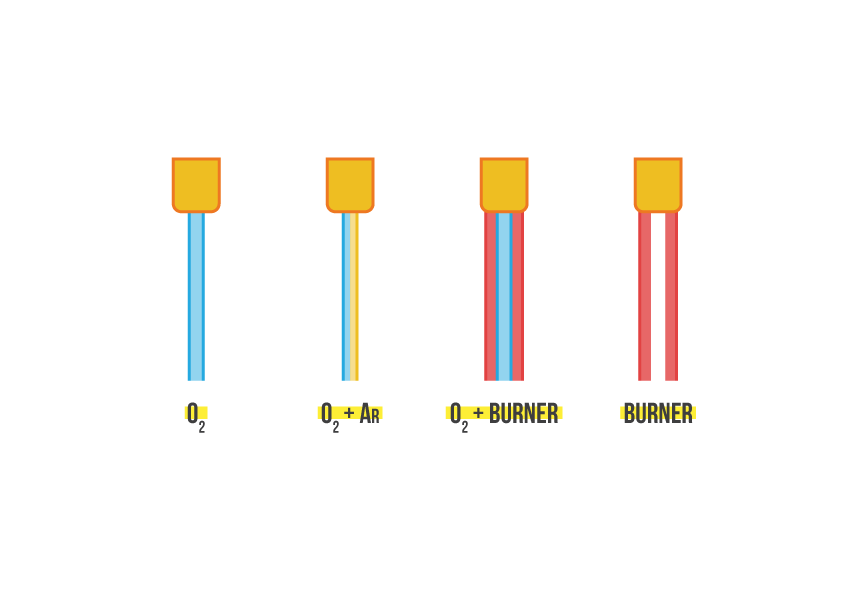

- Tolerance of a large range of oxygen/argon dilution

- Adapted to different sizes of converter

- An oxygen/gas burner configuration can be designed