Soudobeam carries out customised production of welded assemblies and sub-assemblies. Following plans and specifications, we carry out complete manufacturing of the assembly, from supply of materials to delivery.

On the basis of the specifications supplied, we implement all our machining and welding capacities to provide a product that is ready to use, by conducting the required in-production controls to ensure a level of quality that replies to the criteria of the most advanced industries.

To ensure a comprehensive offer and meet specific technical requirements, for thermal or surface treatments in particular, we work with specialist partners or the recommended service providers, according to requests.

Customised guidance

We carry out comprehensive management of the project in keeping with the customer’s requirements and demands in order to provide a fully customised construction. We also conduct follow-up of special technical requests.

- Definition of specifications and review of requirements

- Customised production and in-production controls

- Further works and acceptance testing

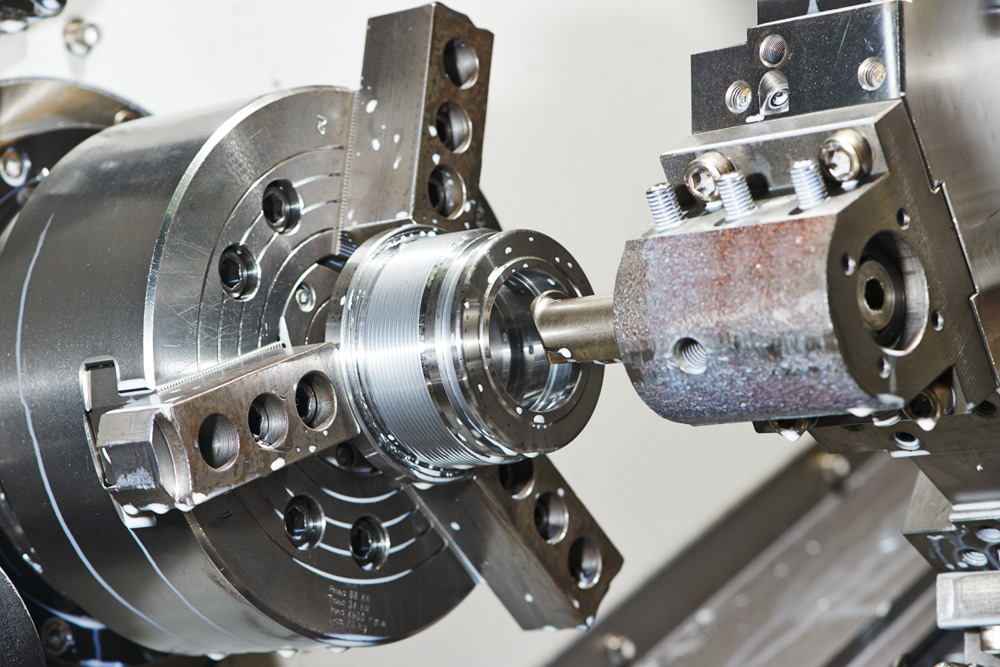

Machining

We are equipped to deal with turning, milling and grinding work in addition to the project. Specifically, this enables us to take charge of preparing welded joints and giving them the precision required for the selected assembly process.

- Conventional turning Ø 600 mm Lg 5,000 mm

- CNC turning Ø 400 mm Lg 2,000 mm

- CNC milling 2,000 mm x 800 mm x 800 mm

Assembling

We carry out assembly by manual or automatic welding of many materials (carbon steel, stainless steel, aluminium, copper, nickel, etc.), according to the design interfaces supplied or defined in collaboration with our design and engineering department.

- Arc welding (EE – TIG – MIG/MAG)

- Electron beam welding

- Technical monitoring by an international welding engineer (IWE)

Forming

We also perform forming thanks to various processes, either in-house or by collaboration with our out-sourcing partners, as well as designing and producing cupping tools.

- Cupping

- Tool design

- Technical monitoring